Construction, Materials and the Core

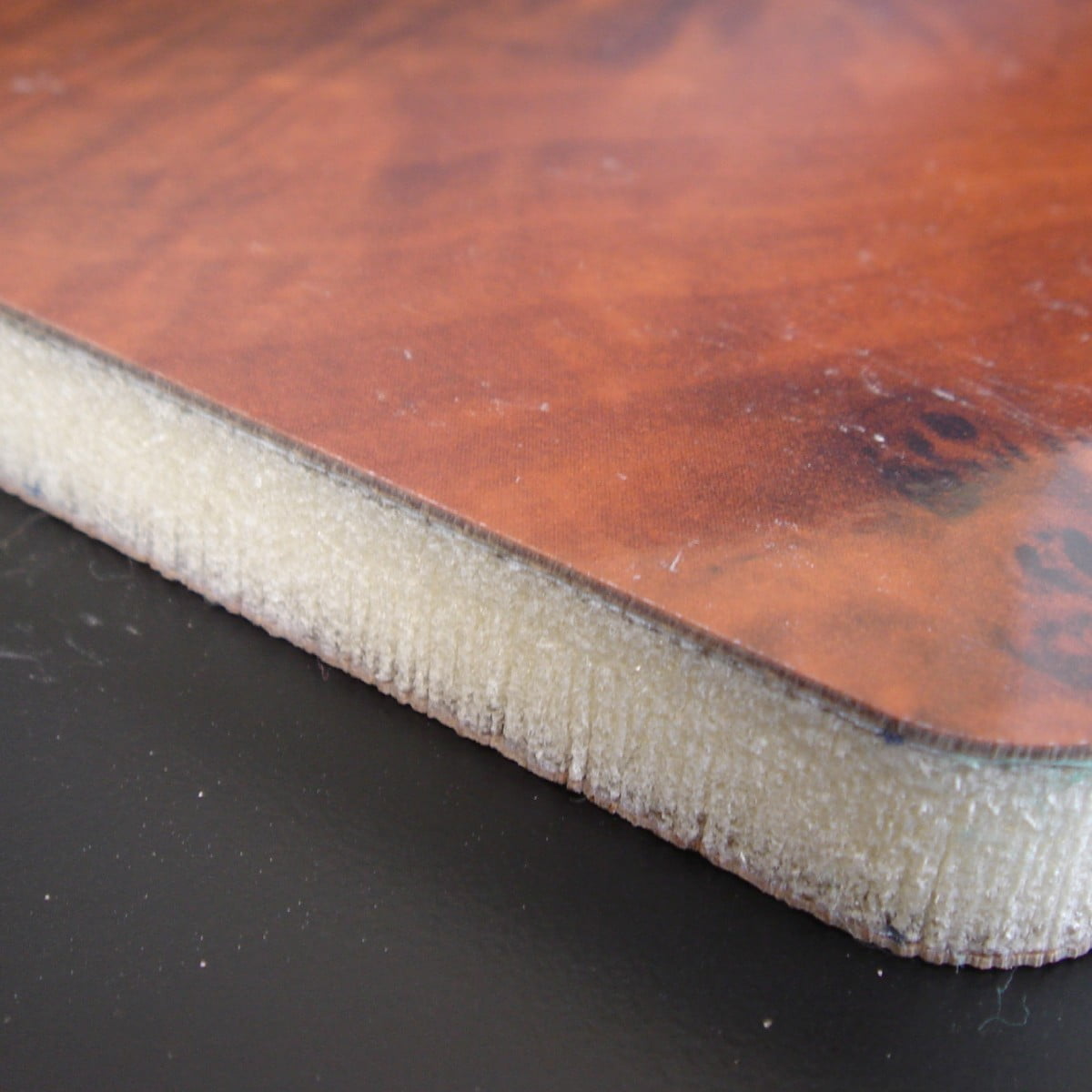

Sandwich Material Construction

There are three components to any sandwich material: the facing, the core and the glue that holds it all together. Each of these will affect the material’s weight, strength and performance characteristics. Generally, the faces are extremely strong, while the core is lightweight and much weaker, but with an excellent adhesive, the benefits of both can be realised.

Composite Panel Facing Materials

Facing materials vary enormously. They can be purely functional or purely cosmetic. Most are a combination. Facing materials are either composite or non-composite. Non-composites, i.e. timber veneers, metallic sheets, plastic sheets, melamine, etc., are manufactured first and then incorporated into the sandwich. Composite facings can be laminated directly onto the core material, reducing manufacturing time and the finished composite panel’s weight, or they can be premanufactured, but many are only cured during the sandwich finishing process.

The Core

The second part of the sandwich is the core. The core of the material performs two principal functions: it keeps the sandwich faces the correct distance apart during bending or compressive loading, and it prevents them from sliding over one another under shear loads. For this, core materials need to have suitable strength and stiffness qualities.

Apart from the aerospace industry, which generally uses honeycomb or corrugated materials, the most commonly used core materials for sandwich construction are expanded thermoset and thermoplastic foams. These foams can be closed-cell, open-cell, or a mixture of closed- and open-cell. Almost any polymer can be foamed, but the most frequently used in sandwich structures are polyurethanes (PUR), polystyrenes (PS), polyvinylchloride (PVC), polymethacrylimides (PMI), polyetherimides (PEI) and polyphenolics (PF). Some can be performed on complex shapes before they are faced, and some, such as polyurethanes (PUR), can be foamed between the pre-constructed faces of the sandwich, allowing even more complex shapes to be made in these materials.